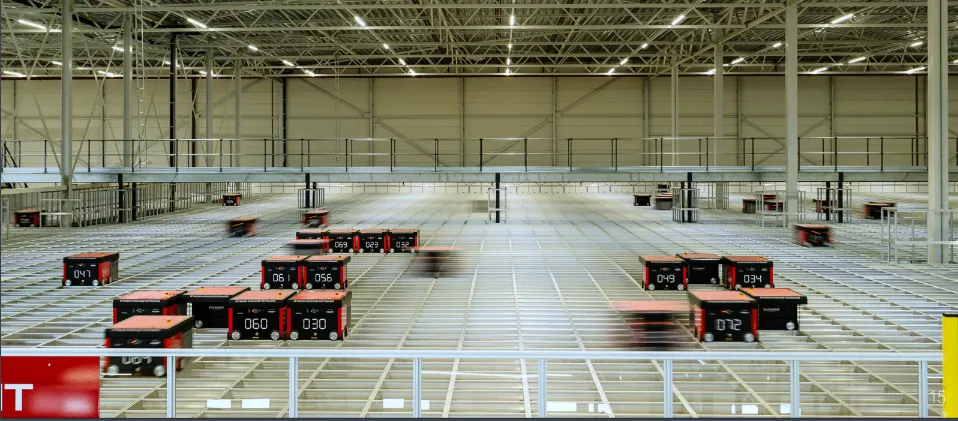

SSI Schäfer Miniload

SSI Schäfer Miniload from 2012 – Efficient, Automated Storage and Picking Solution

Relevator now offers a high-performance SSI Schäfer Miniload system from 2012 in excellent condition. This solution is an automated high-bay warehouse specifically designed to handle small items with maximum efficiency. Ideal for businesses in e-commerce, retail, and wholesale sectors needing fast order processing and optimized use of storage space.System Structure and Functionality

The Miniload system consists of:• 10 shelving sections with a total of 17,480 storage locations.

• 5 cranes ensuring quick and precise handling of the bins.

• Conveyor belts for smooth transport to and from two efficient picking stations

How the system works:1. Goods are repacked from cartons into storage bins at an input station.

2. The bins are automatically transported via conveyor belts to the Miniload system's high-bay storage.

3. 5 cranes retrieve the required bin, manage in-/outbound storage, and place the bins on the conveyor belt.

4. At the picking stations, the picker receive clear instructions via a computer on which products to pick.

Each picking station can handle up to seven bins simultaneously, providing efficient and user-friendly order picking.Storage Capacity and Performance

| Number of Sections | Number of Storage Locations per Section | Total Number of Storage Locations |

| 3 sections | 3 540 storage locations | 10 620 storage locations |

| 1 section | 3 432 storage locations | 3 432 storage locations |

| 1 section | 3 428 storage locations | 3 428 storage locations |

| Total | 17 480 storage locations |

The storage capacity consists of a total of 17,480 bins. The recommended usage is 95% capacity—approximately 16,600 bins — for optimal operation. Each bin measures 599 mm x 399 mm x 270 mm and has a storage volume of 64 dm³, providing a total storage volume of 1,062,784 dm³. The bins are robust and can handle a maximum load of 40 kg per bin.

Performance: The Miniload system can process up to 3,400 order lines per day during an 8-hour shift.

Service and Condition

• Complete service performed by SSI Schäfer every six months

• Service documentation available.

• The system is in excellent condition and well-maintained.

Price

• Original Price (2012): 3.5 million EUR

• Estimated New Price Today: 4.4+ million for a similar solution

• Included in the Price: The Miniload system, Two compressors, All conveyor belts and storage bins.

Availability and Additional Information

• Dismantling available from May 2025.

• Price excludes dismantling, transport, and installation.

• System and conveyor belt blueprints are available.

• Interested parties can book a visit to see the Miniload system in operation.

This SSI Schäfer Miniload presents a unique opportunity to invest in an automated storage solution that combines efficiency, precision, and long-term sustainability for your business. Contact us for more information or to book a visit to see the Miniload system in action.Technical information