Picking support for vertical storage systems

When it comes to buying vertical storage systems in the form of vertical carousels or Vertical Lift Modules (VLMs), there are many choices and options to buy – one of them is picking aids. The category of picking aids includes various functions that make it easier for the picker to pick the right item from the right location. In this guide, you can read more about similar picking aids for vertical storage systems and form your own opinion on what might be suitable for you.

First of all – Control systems and WMS

To be able to utilize the picking aids that are available, the basic requirement is first and foremost that you have a control system or WMS where information about picking locations, articles or orders is stored. In the simplest version, the control panel of the storage machine can be used to at least manage picking locations. The control panel on a vertical carousel and Vertical Lift Module is often referred to as a PLC (Programmable Logic Controller) and is the basic control system for the vertical storage system. The PLC itself can also be used for the picking aid. Depending on the vertical storage lift, the PLC may have more or less functionality – basically, it can always be used to select the shelf or picking location. In some cases, the PLC can also manage item data. In short, some advantages and disadvantages of the PLC as a picking tool:

+ Low cost, included in the vertical storage system.

+ Easy if you have a low picking frequency

– Often small display

– No graphic pick image

– Forgetting the picking location can lead to walking/searching time if the machine is wide

Picking aids for vertical carousels

There are mainly two different picking aids available for vertical carousels

LED-list

As a picking aid for a vertical carousel, you can buy a handrail that is mounted along the table under the opening of the vertical carousel. In connection with the presentation of a shelf, the guide strip shows where to pick the goods sideways. The guide strip indicates this by illuminating a point, or a part of the strip that is the same size as the picking location. The ledge gives a shorter search time to the picking location along the 3-4 meter wide vertical carousel.

+ Low cost

+ Easy if you have a low picking frequency

+ Helpful if you have a wide vertical carousel

– Does not show exact picking location

– Does not show item info

Digital list

An upgrade from the LED-list is to have a digital list. A digital list means full flexibility in what you want to show on the list. Usually, the list shows item number, quantity, item description, location on the carrier, etc. A digital list is a very effective picking aid on a vertical carousel where you increase the likelihood of correct picking by being able to present clearer information.

+ Flexibility in what the list should show

+ Increased picking accuracy

+ Suitable for medium/high picking frequency

– Slightly more expensive than LED-list

– Does not show exact picking location (only text)

Picking aids for Vertical Lift Modules

Like vertical carousels the VLM offer both a LED-list and a digital list as a picking aid. However, the differences between the function of the vertical carousel and the VLM mean that there are a few more variants of picking aids for Vertical Lift Module, and the use of LED-list and digital list can be slightly different.

LED-list and digital list for Vertical Lift Modules

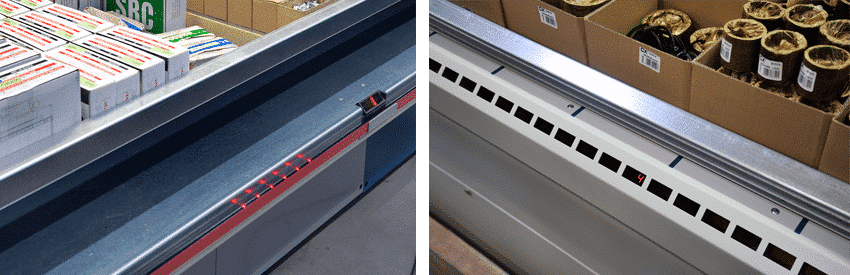

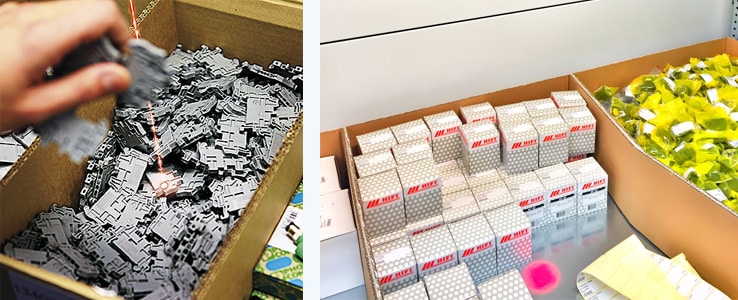

The advantages and disadvantages of the LED-list and digital list for VLMs are very much the same as a vertical carousel – it is a relatively cheap picking aid, and it shortens the search time. Unlike a vertical carousel, the LED-list for a Vertical Lift Module can also display a number illustrating the correct depth location for the pick. The same applies to the digital list. Depending on the supplier, the lists can look different, two examples are shown below.

.

.

In the example on the left, the LED-list indicates the picking location, the number on the display in the middle indicates the deep picking location. In the example on the right, the lateral and deep pick location is shown in the same display.

Laser/ LED pointer

A unique picking aid for Vertical Lift Modules is that a laser/LED pointer shows the exact location to pick goods from. There are several designs for the pointer, but the most common is that a rail in the ceiling of the opening moves to point to the correct location. The light point can come in different formats depending on how many storage spaces you have per tray. If you have many storage locations per tray, the pointer can come with a concentrated laser point, if you have fewer, it can be a larger oval or round LED light. In addition to the number of storage spaces, it is also important to consider the type of goods when choosing a pointer. An LED light is normally preferable as it shows a larger marking. Should you have very densely stored products, a laser may be necessary to show the correct picking location.

+ Pointing to the exact picking location.

+ Goes to the picking position even before the tray arrives (reduces search time)

+ Safe for high picking frequency

– A more expensive option

– Requires periodic maintenance/calibration

Example of laser pointer on the left, guide pointer on the right.

If you are wondering about anything related to picking aids for storage machines, or generally regarding vertical carousel or Vertical Lift Modules, we are at your service.

Contact us through the form below or send an email to info@www.relevator.se!