Investing in vertical storage system?

The first myth we want to dispel is that warehouse automation must cost tens of millions (or more) – sure, fully automated solutions that are more like a factory than a warehouse tend to require large budgets, but entry-level solutions are available for businesses of all sizes. Regardless, before you ask yourself what you can afford, you should ask yourself what it is you are actually looking for?

Efficiency or quality?

And of course you want both! The most common argument for automating the warehouse at all is the possibility of reducing labour costs and reducing the possibility of human error in the processes. With that argument, the questions you need to ask yourself are:

• In which process can we make the greatest efficiency gains?

• And where do our staff make the most costly errors?

Most importantly, when asking yourself these questions, do your own analysis! The tendency when researching automation solutions is to immediately start looking at equipment to streamline picking, and the risk is that vertical storage system offering this type of equipment will reinforce that image for you. In automation, there is no “one-size-fits-all” and even if an industry faces similar challenges, your operation may be unique. Perhaps it’s the inventory that’s causing you problems, you have the wrong item data, or the packing process is consuming your resources? Do the analysis thoroughly.

Space savings?

In addition to efficiency and quality, the space savings offered by different automation solutions can pay for themselves – calculating space savings also tends to be easier than predicting efficiency gains. Based on the following points, you should be able to give an automation provider enough evidence to show how and if their solution can save you space:

• What are the physical conditions of the proposed premises/location – measure the ceiling height and floor area carefully.

• Estimate your volume of goods and not your current storage capacity in volume. Warehouse automation can significantly increase fill rates and avoid air in half-full racks and boxes. To enable a supplier to estimate the space savings of warehouse automation, it is therefore important to report how much you estimate the volume of goods to be, and not how many or how big shelf spaces you have.

If you want to ensure that you get independent support in the calculation of your space savings, logistics consultants such as Logistified can provide good support.

When are Vertical Lift Modules or vertical carousels suitable

Vertical storage systems in general are a very good option if you want to find a simple solution with low maintenance costs, and which can be acquired at a relatively low purchase price.

If you have many articles in your warehouse that are relatively small in size, the space savings that a vertical storage systems offers can be up to 70-80% in comparison with regular shelves. In terms of picking efficiency, it is usually said that a solution with 2-3 vertical storage systems can generate 120 – 250 picking rows per hour on a picker – in comparison, a quick manual picking in a shelf is usually about 60 – 70 picking rows per hour.

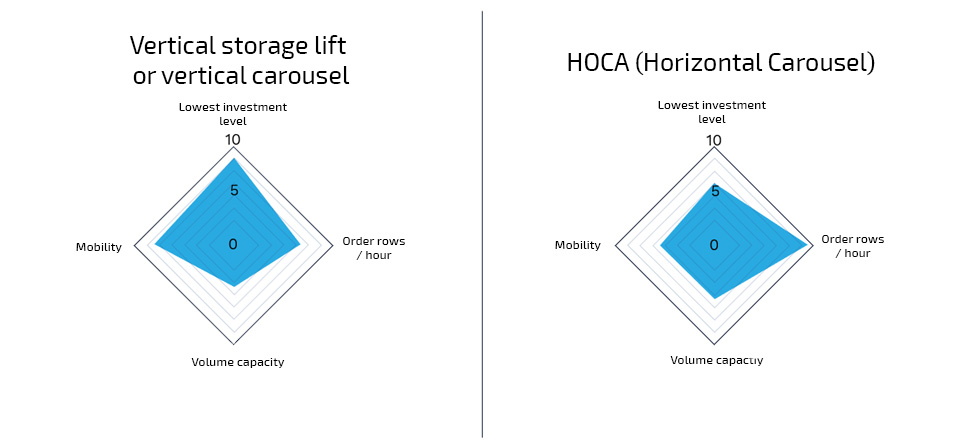

A comparison

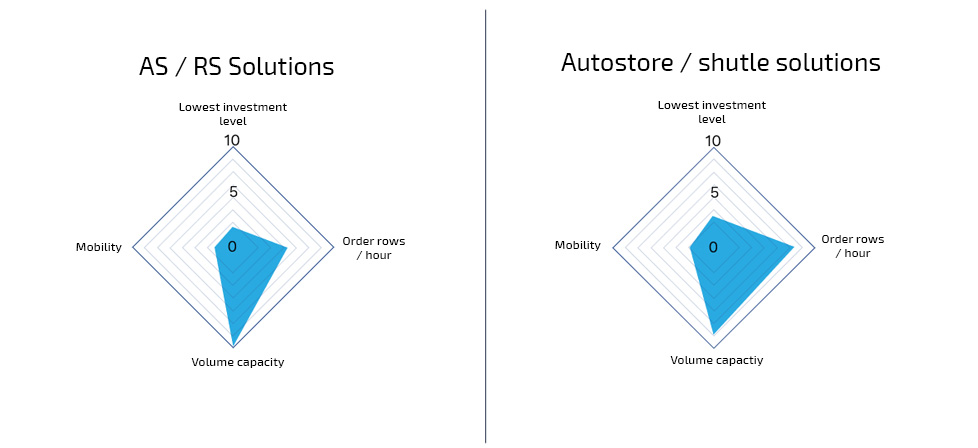

If you are comparing different types of equipment, the illustration below that we at Relevator have designed may be helpful – we have tried to illustrate entry price, efficiency, capacity and mobility (i.e. whether the automation can be dismantled and moved if necessary).

The above assessment is not scientific and may be different for each piece of equipment when assessing other parameters.

If you want to hear more about our experience with different automation solutions, you are welcome to contact us. When it comes to vertical lift modules and vertical carousels we can also help you find suitable equipment from our own range. Use the contact form below, or give us a call!